- +86-13526935931

- gwdlthermo@gwdl.com

GWDLTHERMO atmosphere pusher furnaces are built for continuous production under stable gas atmospheres such as nitrogen, argon, or vacuum. Designed to meet the needs of high-throughput sintering for materials like graphite, ceramics, magnetic components, or metal powders, each furnace offers multi-zone heating, full-sealed structure, and precise hydraulic pushing systems.

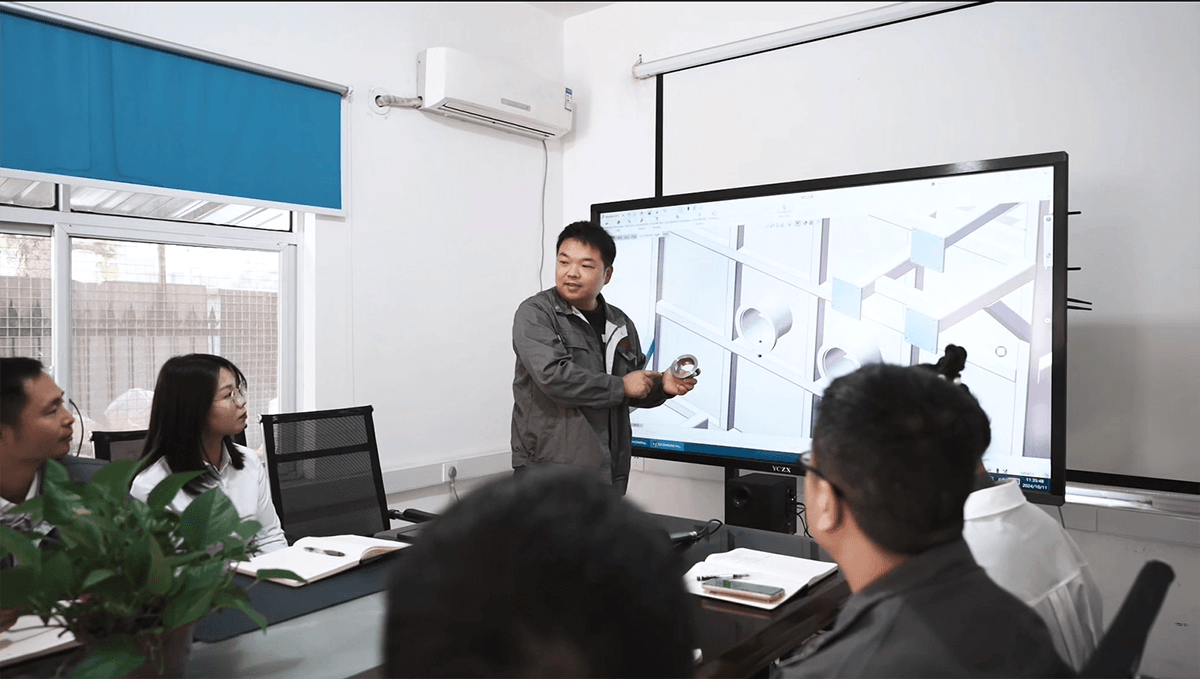

Whether you require fast throughput, high temperature uniformity, or low-oxygen processing, we specialize in fully customized furnace lines. Based on your target capacity, product size, temperature profile, and atmosphere purity, our team will engineer a complete solution—from layout planning to gas flow design and control integration.

Looking to build a continuous sintering system tailored to your material and process? Share your specs—we’ll design it from the ground up.

Discover the 24m continuous pusher plate sintering furnace engineered for ceramic and powder sintering processes up to 1500℃. Equipped with 14 heating zones, hydraulic pusher, and advanced thermal insulation.