- +86-13526935931

- gwdlthermo@gwdl.com

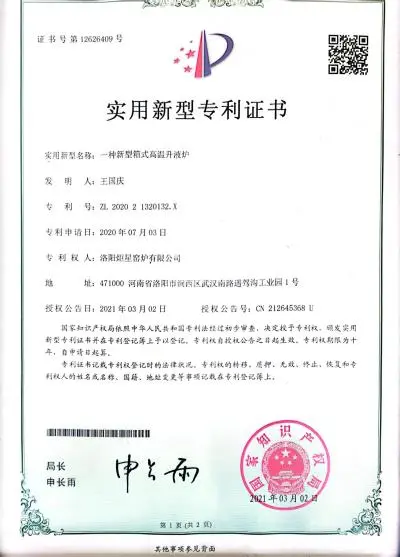

GWDL's independently developed patented technology for the new box-type high-temperature liquid raising furnace adopts an innovative multi-stage heating system and precise conveying technology for liquid materials, realizing stable lifting and accurate pouring of molten metals or ceramic slurries in high-temperature environments (up to 1800℃). Equipped with a special material crucible design and an intelligent air pressure control system, the equipment solves industry problems such as large temperature fluctuations, low liquid raising precision, and easy oxidation in traditional liquid raising furnaces. The liquid raising height control precision reaches ±0.1mm, the temperature uniformity is ±1℃, and energy consumption is reduced by more than 35%. It is particularly suitable for high-end fields such as precision casting and composite material preparation.