- +86-13526935931

- gwdlthermo@gwdl.com

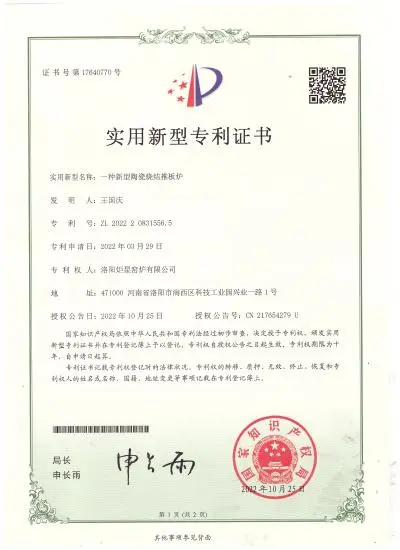

GWDL's patented technology for the new ceramic sintering pusher furnace adopts an innovative multi-stage pusher transmission system and segmented temperature control structure, achieving precise temperature control and uniform heating of ceramic products during the sintering process. Through optimized airflow organization design and a high-efficiency thermal insulation system, the equipment solves industry problems such as uneven temperature, high energy consumption, and product deformation in traditional pusher furnaces. It can achieve a temperature field uniformity of ±1℃, with the product qualification rate increased to 99.2% and energy consumption reduced by more than 35%.