- +86-13526935931

- gwdlthermo@gwdl.com

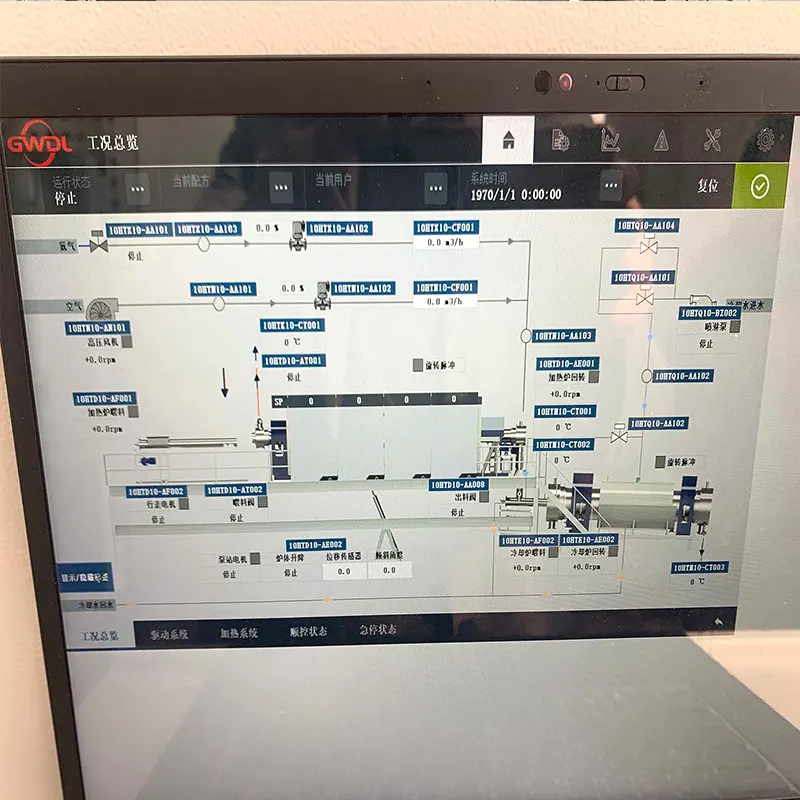

System Overview

The Juxing 9-Zone Temperature Control Cabinet is an industrial-grade temperature control device, typically used in industrial settings requiring precise multi-zone temperature regulation. When integrated with the Siemens WINCC system, it enables advanced monitoring, data acquisition, and process control capabilities.

System Architecture

1. Hardware Components

• Juxing 9-Zone Temperature Control Cabinet main unit

• Siemens PLC controller (e.g., S7-300/400 series)

• Industrial communication network (Profibus/Profinet/Ethernet)

• Host computer running WINCC SCADA system

2. Software Configuration

• Siemens WINCC configuration software

• PLC programming software (STEP 7 or TIA Portal)

• Communication drivers for the temperature control cabinet

Key Points of System Integration

1. Communication Interface Configuration

• Typically achieved via MODBUS RTU/TCP or PROFIBUS DP protocols

• Configure the corresponding communication driver in WINCC

• Set the correct station address, baud rate, and data format

2. WINCC Project Configuration Steps

1. Create a new project and select the appropriate communication channel

2. Add the temperature control cabinet as an external device

3. Define variable tags mapped to the cabinet’s registers

4. Configure alarms and event logging

5. Design the human-machine interface (HMI)

3. Typical Functionality

•Real-time Monitoring: Display current temperature, setpoints, and operational status for each zone

• Parameter Setting:Remotely adjust temperature control parameters via the WINCC interface

• Data Logging: Record temperature curves and store historical data

• Alarm Management:Handle alarms for over-temperature, sensor failures, etc.

• Report Generation: Produce production data statistical reports

Application Advantages

1. Centralized Monitoring:Unified oversight of multiple temperature control cabinets’ operational status through WINCC

2. Data Traceability: Complete recording of temperature change processes to meet quality traceability requirements

3. Remote Operation: Reduce on-site interventions and improve work efficiency

4. System Integration: Seamless connection with other factory automation systems

5. Flexible Expansion: Easy scalability and functional upgrades

Common Issues & Solutions

1.Communication Interruption:Check physical connections, communication parameter settings, and termination resistor configurations

2. Data Not Updating:Verify correct variable address mapping and reasonable communication cycle settings

3. Control Delay:Optimize communication load and minimize unnecessary data transmission

4. Permission Issues: Review WINCC user management configurations to ensure proper operation permissions

Maintenance Recommendations

1. Regularly back up WINCC project files

2. Monitor communication load to avoid network congestion

3. Periodically calibrate temperature sensors

4. Keep system software and firmware versions updated

This integration solution is particularly suitable for multi-zone temperature control applications in industries such as food processing, pharmaceuticals, and chemicals, significantly enhancing the automation level and quality control capabilities of production processes.