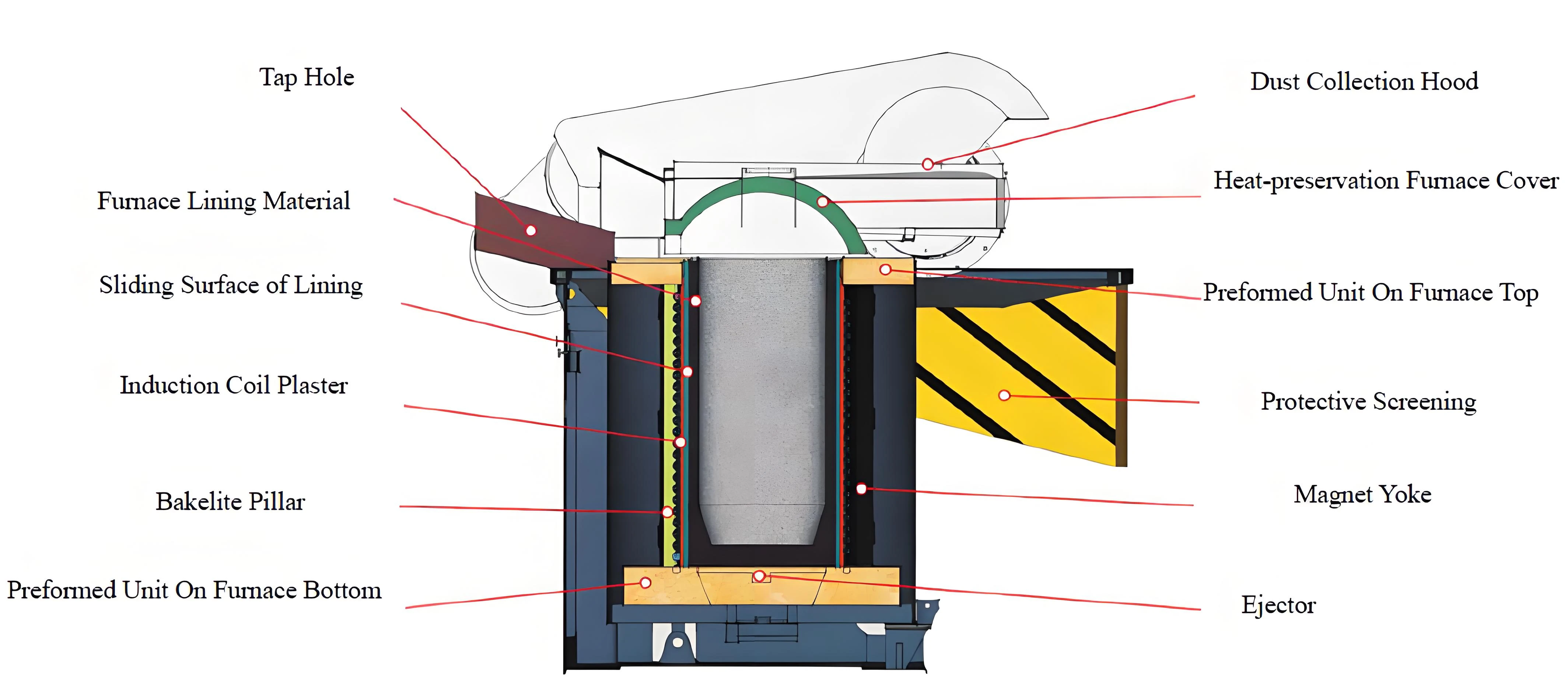

3T Hydraulic Tilting Medium Frequency Induction Melting Furnace

Utilizing an induction voltage of up to 5600V and a high-capacity capacitor bank of 4000KF, it effectively reduces reactive current by 60%, achieving energy savings of up to 200 kWh per ton of molten iron.

Equipped with a hydraulic tilting system and an extra-large heat-resistant steel furnace shell, it is stable, durable, and safe to operate.