- +86-13526935931

- gwdlthermo@gwdl.com

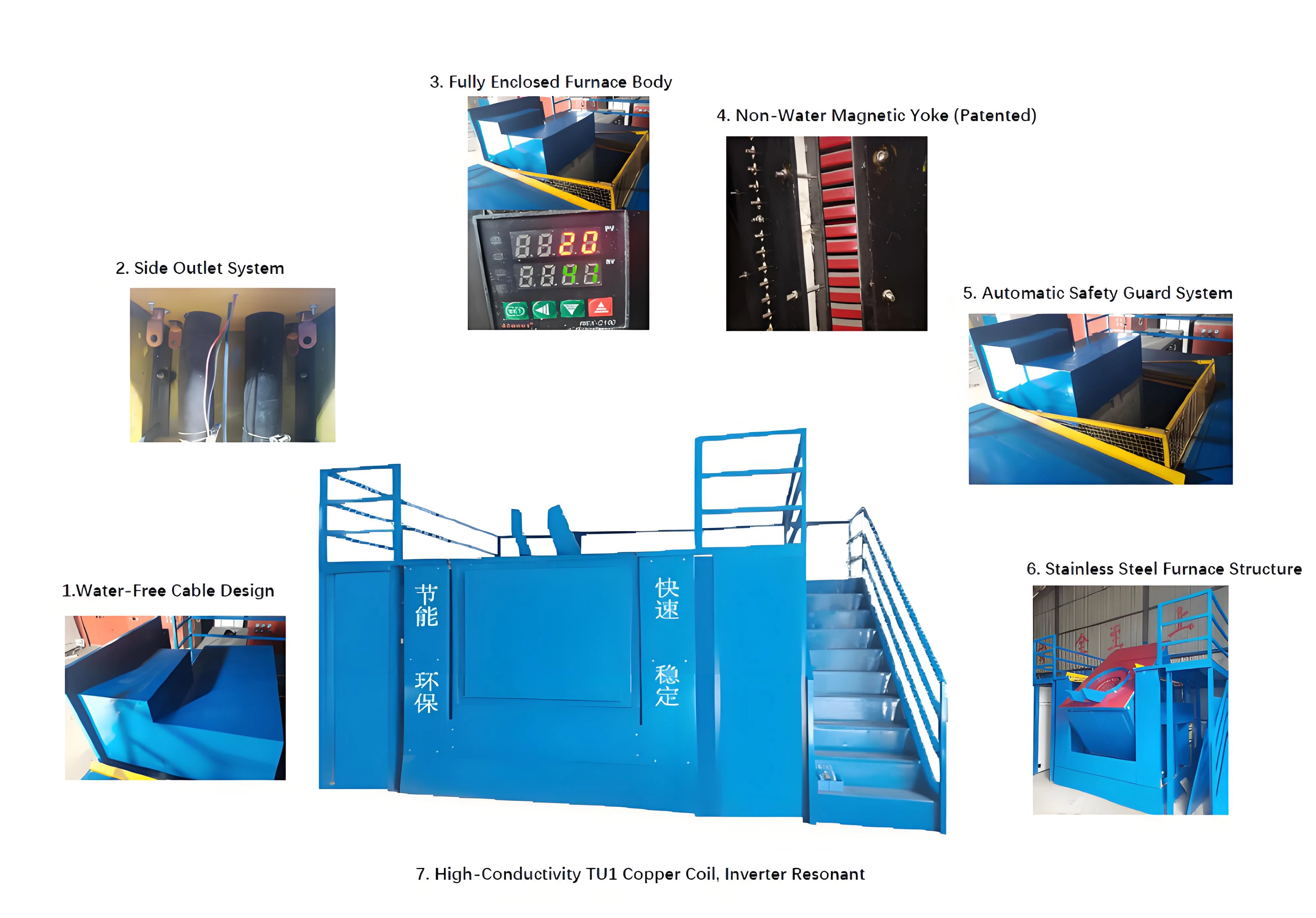

Unlike traditional medium frequency induction furnaces that rely on water-cooled cables — which are prone to leakage, core fracture, and energy loss — our next-generation furnace eliminates water-cooled cables completely. By replacing them with two standard 120 mm² flexible copper cables, we reduce failure points, eliminate internal cable heat loss, and improve overall energy efficiency.

No leakage. No overheat. No maintenance. Just power and performance.

We reimagined the wiring and piping structure by embedding all cables and water lines within the furnace body. The result:

No exposed wiring

Zero contact risk

Clean and organized layout

Unlike conventional rear-mounted connections that twist and wear with furnace tilting, our patented side-outlet system places all connections at the center-side — the most stable point during tilt motion — ensuring extended lifespan and minimal maintenance.

Induction coil arc faults caused by moisture, dust, or oxidation are among the top causes of unplanned downtime. Our sealed furnace body incorporates:

These features guarantee a clean, dry, and stable environment, dramatically reducing arc risks and extending the coil's lifespan.

Traditional furnaces often reuse 50 Hz silicon steel from transformers as magnetic yokes, which is mismatched for medium frequency (300–1500 Hz) and causes overheating and high energy bills.

Our furnace adopts high-frequency magnetic materials with superior permeability and heat resistance, eliminating the need for water cooling, significantly reducing energy consumption, and increasing stability.

Operator safety is paramount. Our built-in system features:

The guard system ensures both operator safety and protection from scrap or debris falling into the furnace pit.

Conventional steel frames are conductive and magnetic, posing risks under high electromagnetic fields. We use oversized 201 stainless steel for the furnace body — offering:

The induction coil contributes to 20% of the total energy loss. We address this with:

The result: reliable coil life, reduced heat loss, and superior safety performance.

Our patented inverter with capacitive-inductive dual filtering delivers:

Compared to traditional series inverters, our system significantly reduces grid pollution while improving efficiency.

We offer customizable induction melting furnaces for aluminum, copper, iron, stainless steel, and more. Available in 500kg to 10+ ton capacities. Contact us for a tailored solution that fits your process needs.