- +86-13526935931

- gwdlthermo@gwdl.com

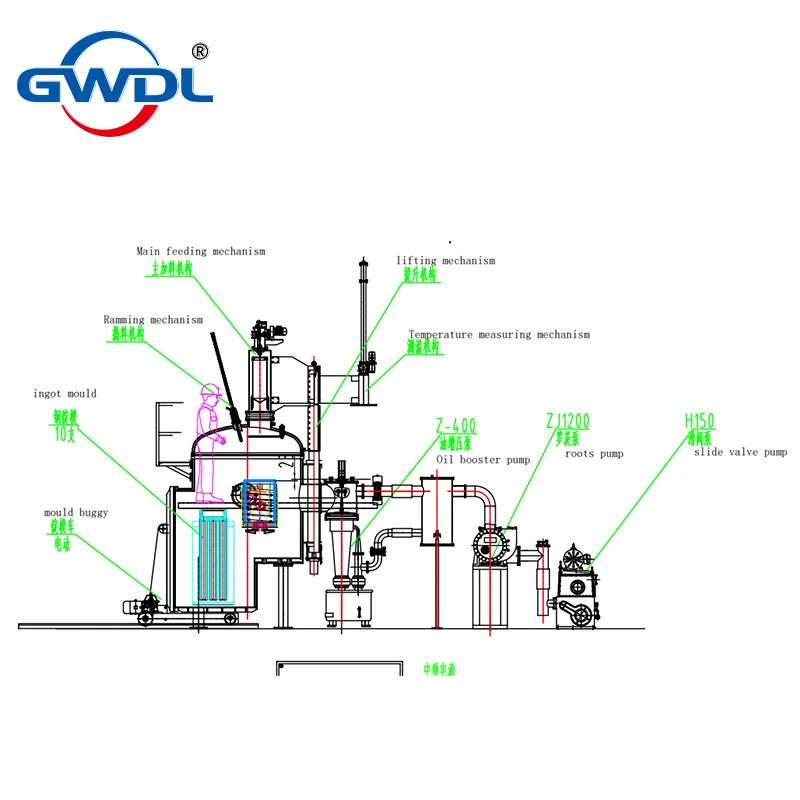

The GWDL vacuum induction melting furnace is a fully integrated system that utilizes medium-frequency electromagnetic induction to melt metals under vacuum or inert gas protection. It’s widely used in the production of superalloys, specialty steels, rare earth materials, and precious metals, delivering ultra-clean, high-purity results with excellent thermal control.

The vacuum induction melting furnace adopts the principle of medium-frequency induction heating and is equipped with a high-vacuum unit to achieve the melting of metals under high-vacuum conditions. It is widely used in the research and production of nickel-based and other special steels, precision alloys, metals with relatively active chemical properties (which are prone to chemical reactions), high-temperature alloys, and magnetic materials. It can also be used for the vacuum precision casting of small parts.

| Model | Capacity (kg) | Frequency (Hz) | Power (kW) | Vacuum Limit (Pa) | Water Usage (t/h) |

|---|---|---|---|---|---|

| GWDL-RLL-10 | 10 | 3000 | 60 | 6 × 10⁻³ | 10 |

| GWDL-RLL-25 | 25 | 2500 | 120 | 6 × 10⁻³ | 15 |

| GWDL-RLL-50 | 50 | 2000 | 160 | 6 × 10⁻³ | 25 |

| GWDL-RLL-100 | 100 | 2000 | 200 | 6 × 10⁻³ | 30 |

| GWDL-RLL-200 | 200 | 1000 | 200 | 6 × 10⁻³ | 35 |

| GWDL-RLL-300 | 300 | 800 | 250 | 6 × 10⁻³ | 40 |

| GWDL-RLL-500 | 500 | 800 | 350 | 6 × 10⁻³ | 50 |

| GWDL-RLL-1000 | 1000 | 800 | 400 | 6 × 10⁻³ | 70 |