- +86-13526935931

- gwdlthermo@gwdl.com

Features

Applications

Firing management and statistical quality control management of fine ceramics, electronic ceramic materials, ceramic products, etc.

Place the temperature-indicating pellet in the furnace and fire it together with the product. After firing, take it out once it cools down to room temperature, and measure its dimensions with a caliper.

Please note: Keep it at room temperature for more than 1 hour.

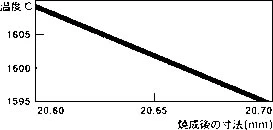

Compare the measured dimensions with the table below, and use the indicated temperature as the management index. The indicated temperature is not the actual physical temperature, but a comprehensive heat-receiving index that integrates the conditions of the fired product. This indicated temperature corresponds to the set temperature under firing conditions of a heating rate of 200℃/hour, a holding time of 2 hours, and a cooling rate of 300℃/hour.

| Dimension (mm) | Temperature (℃) |

|---|---|

| 20.65 | 1601 |

| 20.66 | 1600 |

If this product is used in a vacuum furnace or a furnace with low oxygen concentration, some components may evaporate, which could contaminate the high-temperature electric furnace. Users must pay full attention to this.

| Serial Number | Operating Temperature Range (℃) | Indication Accuracy (℃) |

|---|---|---|

| H | 1400~1700 | ±1 |

| M | 1200~1500 | ±1 |

| L | 1050~1300 | ±1 |

| L1 | 800~1150 | ±1.5 |

| L2 | 600~900 | ±1.5 |