- +86-13526935931

- gwdlthermo@gwdl.com

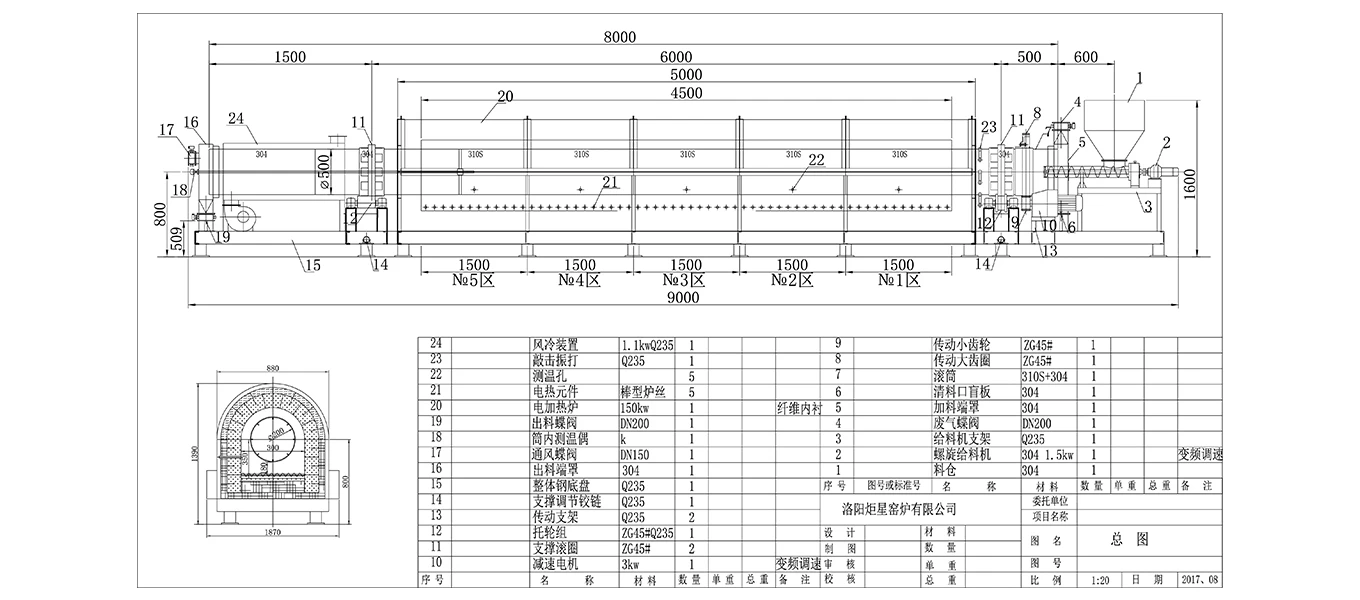

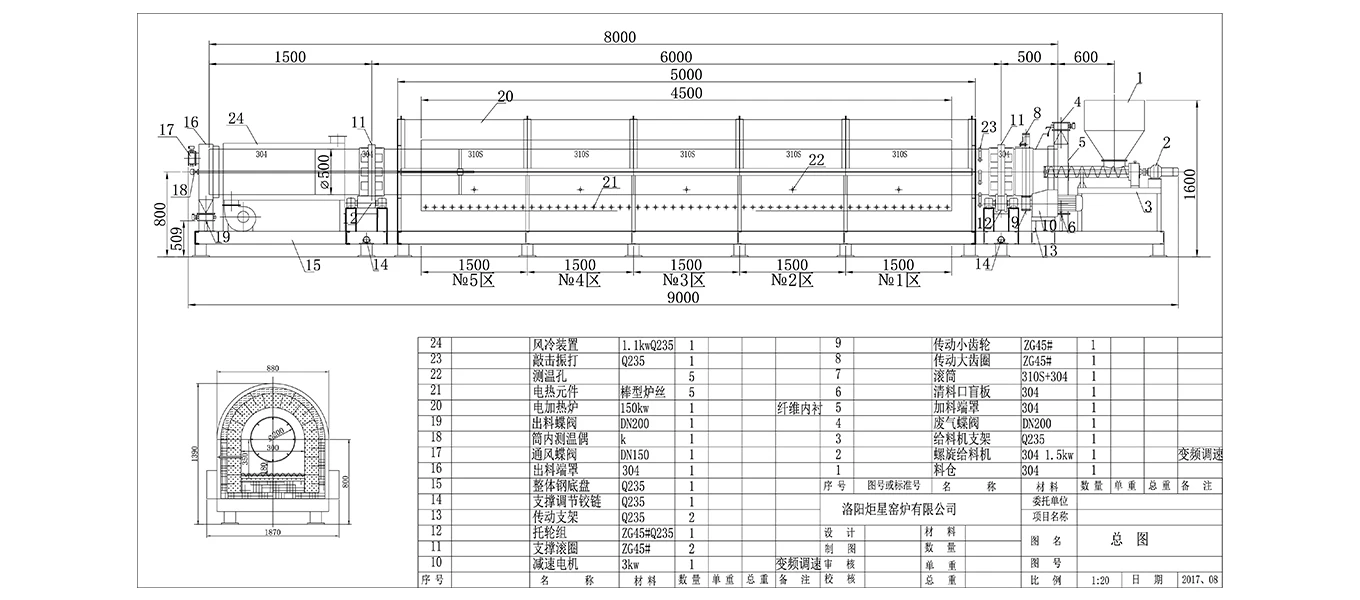

GWL-SSR series rotary kiln is designed for continuous high-temperature processing of ceramics, new materials, and metallurgical products. Featuring automatic feeding and discharging systems, the furnace supports uninterrupted, high-throughput operation with minimal human intervention. Its split-type design with independent control cabinet, intelligent PID temperature regulation, and energy-saving insulation makes it ideal for large-scale industrial production environments demanding 24/7 continuous operation.

1. Continuous High-Volume Production

Supports long-duration, uninterrupted batch or continuous processing with automatic screw-feeding system and extended cooling discharge section, suitable for mass production needs.

2. Fully Automatic and Unattended Operation

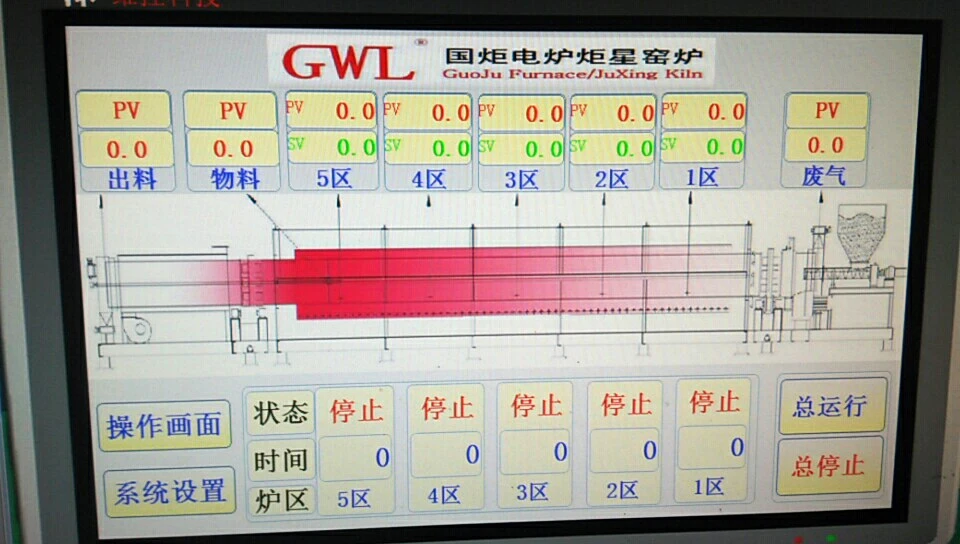

Equipped with touch screen control, programmable temperature curves (up to 30 segments), and integrated feed/discharge mechanisms, the kiln allows fully automated operation, remote monitoring, and real-time parameter adjustment.

3. Energy-Saving and Uniform Heating

Utilizes vacuum-formed alumina lightweight insulation and high-temperature alloy heating elements. Multi-layer thermal insulation ensures outer shell temperature stays below 45°C, reducing heat loss and improving safety.

4. Intelligent Control and Safety System

Incorporates PID temperature control, SCR triggering, closed-loop feedback, multi-zone temperature regulation, and fault protection including over-temperature, overcurrent, and phase loss protection.

5. Modular Design with Adjustable Tilt & Speed

Dual-screw lift system adjusts tilt angle (1–15°) to control material flow rate; drum rotation speed adjustable between 1–30 r/min. Furnace body and feeding pipe can be customized per process needs.

6. Industrial-Grade Build Quality

All-steel CNC-fabricated structure with powder coating and acid/alkali resistance. Export-grade finish ensures long-term stability, corrosion resistance, and ease of maintenance.

| Parameter | Specification |

|---|---|

| Model | GWL-1000SSR |

| Max Operating Temp. | 950°C |

| Recommended Working Temp. | 900°C |

| Temperature Range | 80–950°C |

| Voltage / Power | AC 380V, 16 kW |

| Heating Element | High-temperature alloy resistance wire (Mo alloy) |

| Temperature Accuracy | ±1°C (No overshoot, closed-loop control) |

| Heating Rate | Adjustable: 1°C/h to 30°C/min |

| Thermocouple | Type K (0–1320°C range) |

| Heating Zones | Dual-side heating |

| Furnace Structure | Dual-layer air-cooled steel shell |

| Shell Temperature | ≤45°C |

| Insulation Structure | Four-layer insulation: alumina fiber + board + bricks |

| Feeding System | Stainless steel screw feeder, 150mm × 1800mm |

| Discharge Cooling Zone | 2300mm cooling section (final output temp. ≤50°C) |

| Tilt Adjustment | 1–15°, motorized dual-lead screw system |

| Rotation Speed | 1–30 r/min (adjustable) |

| Display Interface | Touch screen with real-time process monitoring |

| Curve Programming | 30-segment programmable profiles, multi-curve input |

| Communication Interface | RS485, USB export, printer port |

| Safety Features | Over-temp, over-voltage, over-current, sensor failure, etc. |

| Accessories Included | Heating elements ×2, tongs, gloves, manual, certification |

| Warranty | 1-year (heating elements: 3-month replacement if damaged) |

With over 20 years of experience in thermal equipment engineering, our team is deeply committed to delivering customized solutions that meet the unique challenges of each industrial application. Whether supporting pilot-scale innovation or full-scale production, we work closely with our clients to co-develop furnaces that ensure both performance and reliability. Every rotary kiln we build reflects not only our technical precision, but also our long-standing dedication to helping clients succeed in complex, large-scale projects. We believe in partnerships built on trust, service, and shared progress.