- +86-13526935931

- gwdlthermo@gwdl.com

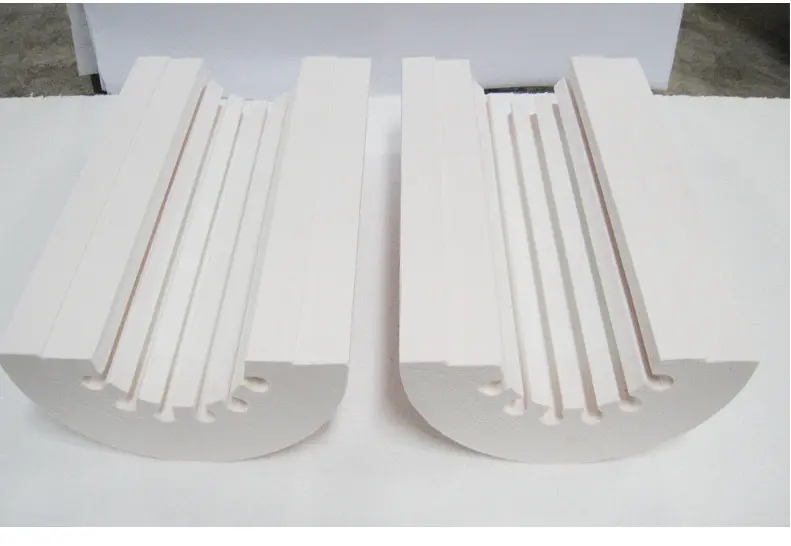

The fiber heating module is manufactured by embedding resistance wires into fibrous materials through a special process, forming a single fiber electric heating element. Resistance wire arrangement can be in W / Z / O types, and molding methods include mosaic and embedded. Operating temperature: 300–1300℃.

Due to its unique advantages, it is regarded as an ideal alternative to traditional resistance heating components.

The GWDL-XK energy-efficient resistance furnace adopts vacuum-formed refractory fiber as the furnace chamber, achieving up to 40% energy saving. Tested to meet the National C-Level furnace standard, it features: rapid heating/cooling, precise temperature control, uniform furnace temperature, and lightweight design.

| Category | Details |

|---|---|

| Brand | GWDL |

| Material | Ceramic fiber / Alumina |

| Product Name | Ceramic Fiber Furnace Lining / Alumina Furnace Chamber |

| Design Temperature | Ceramic fiber: 200–1200℃ / Alumina: 1300–1700℃ |

| Energy Saving Rate | 20–40% |

| Heating Method | Resistance wire, silicon carbide rods |

| Resistance Wire Layout | Zigzag or spiral |

| Forming Method | Mosaic / Embedded |

| Specifications | Customizable upon drawings |