- +86-13526935931

- gwdlthermo@gwdl.com

The circular furnace body is engineered to evenly distribute external atmospheric pressure, avoiding stress concentration and delivering greater structural stability under vacuum. Its seamless cylindrical design also ensures superior airtightness, reducing the risk of leakage and making it ideal for high-vacuum applications down to 10⁻³ Pa.

| Parameter | 1400°C Model |

|---|---|

| Max. Operating Temp. | 1400°C |

| Long-Term Use Temp. | 1350°C |

| Control Range | 50–1400°C |

| Temp. Sensor | S-type thermocouple (0–1700°C) |

| Control Accuracy | ±1°C (no overshooting) |

| Heating Elements | Silicon carbide rods/ Silicon molybdenum |

| Installation Position | Installation Position |

| Heating Rate | Adjustable: 1°C/h (min, non-leaner) – 40°C/min (max, non-leaner) |

| How To Replace The Heating Element | The sealed top cover lifts mechanically and rotates 360°, providing full access while minimizing downtime. |

Item name | Touch screen function |

|---|---|

Size | 7 inch TFT true color |

Dimension | 206W*156H*50D(mm) |

Resolution | 800*480 |

Backlight | LED |

Wattage | 5W |

Weight | 1Kg |

LANGUAGE | Chinese/English (customizable) |

Full screen display and operation | Instrument screen, light bar graph, historical trend, data report, alarm information, data export, process flow, system management, etc. |

Control object | Temperature, pressure, flow, liquid level, etc. |

Number of control furnaces | 1-6 sets |

Temperature control | Touch screen + high-precision integrated module |

Starting temperature rise | Touch operation |

Temporary warming | Touch Operation |

Stop warming | Touch Operation |

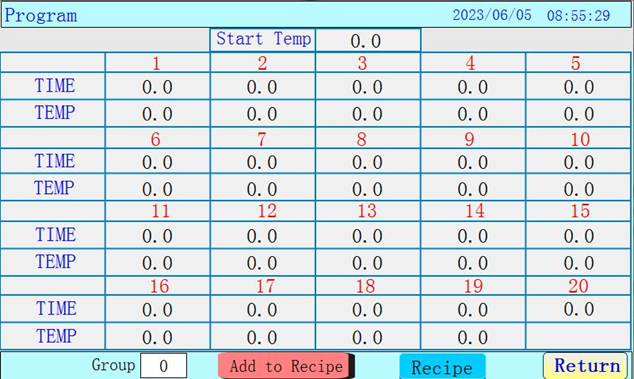

Temperature curve preparation | Touch operation, 30 segments per curve |

Temperature curve storage quantity | Unlimited (each curve can be named in Chinese/English) |

Real-time status display | Running curve name, running section number, time, section running time, digital temperature, real-time curve, 100% power output |

Select segment number start (cross-segment start) | Touch operation |

Curve range | Adjustable |

History curve (graphic) | Approx. 20 months of storage |

Data report (EXCEL) | Approx. 20 months of storage, simultaneous display of multiple points (can be expanded by inserting a USB flash drive) |

Interval time between history curves and report records (disk storage) | Adjustable from 1 to 3600 seconds, multi-point simultaneous display (can be expanded by inserting a USB flash disk) |

Alarm indication | Color change (red) |

Alarm information language | Chinese/English display (alarm time and event description) |

Data export interface | USB |

Printer interface | Parallel port |

Operation touch screen protection | With password setting (others without password, prohibit operation) |

Communication port | RS485 |