- +86-13526935931

- gwdlthermo@gwdl.com

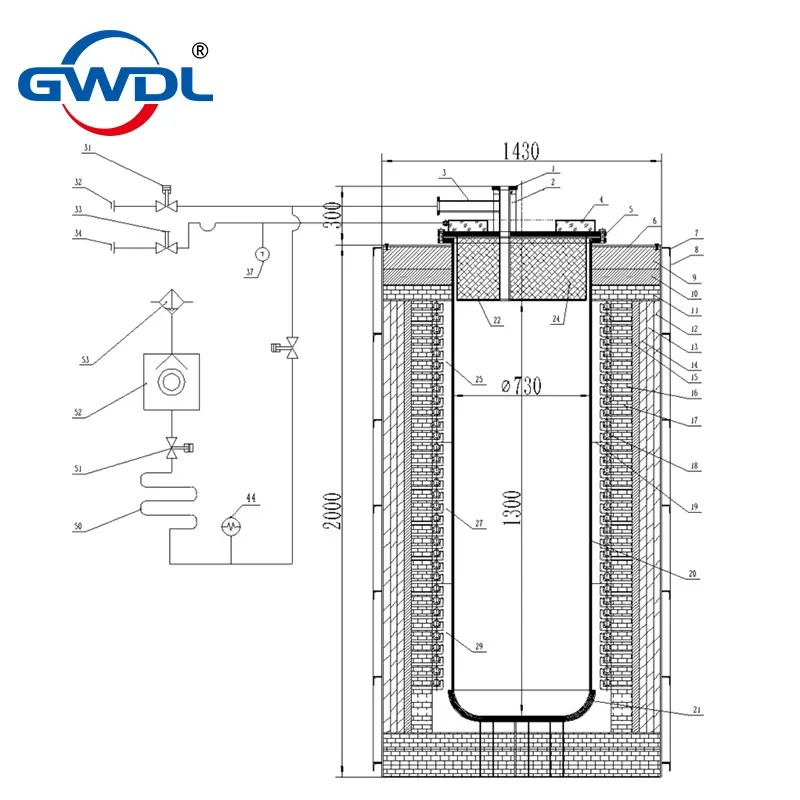

This 1100℃ vacuum atmosphere pit-type furnace is designed for heat treatment processes that require a vertically loaded chamber and a controlled environment. Ideal for industries such as aerospace, automotive, and precision tool manufacturing, this furnace provides uniform heating and excellent temperature control for applications including annealing, stress relieving, and aging of metal parts.

With a split-type structure, the furnace body and control system are independently arranged. The inner chamber adopts high-purity alumina fiber insulation and a refractory brick base, ensuring both thermal efficiency and long-term durability. Heating elements are made of high-temperature alloy resistance ribbons, enabling fast heat-up and stable operation within a vacuum or inert gas atmosphere.

| Feature | Specification |

|---|---|

| Model | GWDL-ZQJ |

| Max Temp | 1100°C |

| Working Temp | 50–1100°C |

| Heating Zones | Top / Middle / Bottom (3-zone control) |

| Temperature Accuracy | ±1°C (no overshoot) |

| Temperature Uniformity | ±5–8°C (DIN 17052-1) |

| Heating Elements | High-temp resistance wire (with molybdenum) |

| Heating Layout | Circular side-wall layout with mechanical protection boards (corundum-mullite, grooved for convection) |

| Furnace Chamber Size | Φ800 × 1300 mm |

| Effective Heating Zone | Φ730 × 1000 mm |

| Lid Mechanism | Hydraulic lifting |

| Vacuum System | Dual-stage rotary vane pump (customer-supplied) |

| Vacuum Gauge | -0.1 MPa analog (digital optional) |

| Gas Flow Control | 2x float flow meters (digital MFC optional) |

| Gas Atmospheres Supported | H₂, N₂, Ar, CO, O₂ (with safety interlocks) |

| Pressure Control | Contact gauge or sensor-based overpressure protection |

| Insulation | Triple-layer: Alumina blanket + fiber board + polycrystalline alumina board (350 mm thick) |

| External Temp | ≤45°C (continuous operation) |

| Shell Finish | CNC steel, acid-washed, phosphated, powder-coated dual-color |

| Controls | Touchscreen + PID/AI controller, 50-segment programmable curves |

| Protection | Dual-loop circuit, over-temp, under-temp, phase-loss, over-voltage/current, sensor failure, soft start |

| Data Display | Temp, segment, time, remaining time, %, V, A |

| Power Rating | 105 kW |

| Voltage Input | 380V (furnace), 220V (control) |

| Cooling | Air-cooled shell, customer-provided water-cooling for lid and port |