- +86-13526935931

- gwdlthermo@gwdl.com

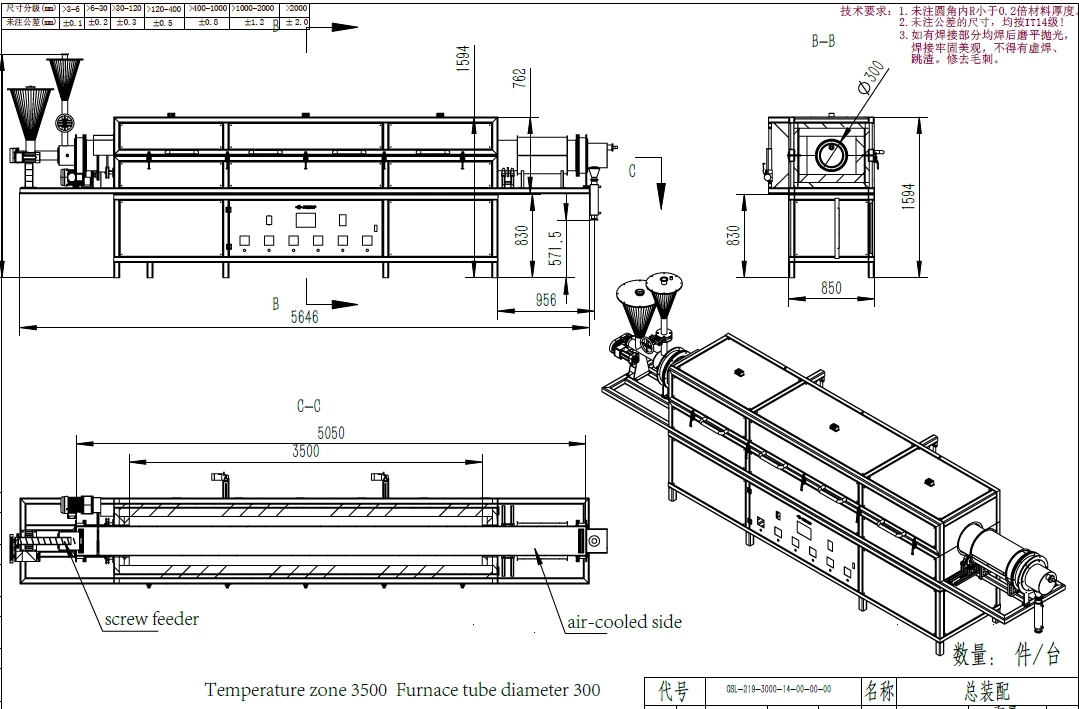

This 1000℃ Tilting Rotary Electric Furnace is specially designed for continuous processing of powders and granular materials with enhanced uniformity and anti-sticking performance. The internal welded loading plate, made from the same 316L stainless steel as the furnace tube, combined with hammers at both ends, effectively prevents material adhesion on the tube wall, ensuring smooth material flow and reduced downtime.

| Parameter | Specification |

|---|---|

| Design Temperature | 1000℃ |

| Model | GWL-KQGA-3 |

| Power Supply | AC 380V ±10% |

| Dimensions (L×W×H) | 6000×1500×1900 mm |

| Power | 70 kW |

| Furnace Tube Diameter | 300 mm (316L stainless steel with internal welded loading plate) |

| Heating Zones Length | 3 zones, each 1333 mm, total 4000 mm |

| Number of Temperature Zones | 3 |

| Temperature Control Accuracy | ±1℃ |

| Tube Rotation Speed | 0–5 rpm (adjustable) |

| Temperature Uniformity | ±5℃ (dependent on heating zone size) |

| Heating Elements | High-temperature alloy resistance wire (with molybdenum) or silicon carbide rods |

| Heating Element Position | Around the furnace tube |

| Temperature Measurement | Nickel-Chromium-Nickel-Silicon K-type thermocouple (0–1350℃) |

| Feeding Method | Spiral feeder with anti-jamming device |

| Furnace Tilt Angle | 0–30°, adjustable |

| Furnace Body | CNC-machined, polished, pickled, phosphated, powder-coated, high-temp baked finish; corrosion & oxidation resistant |

| Furnace Body Cooling | Air-cooled double-layer structure with airflow guiding baffles |

| Insulation | Triple-layer: silica alumina fiber board + alumina fiber board + polycrystalline alumina fiber board |

| Surface Temperature | ≤ Room Temp + 25℃ (continuous operation) |

| Control System | Integrated modular control with dual loop, PID, and protection for overcurrent, overvoltage, etc. |

| Display | 7" full-color touchscreen, multi-curve programmable temperature control (up to 30 segments) |

| Exhaust Ports | Two: DN65 valve top exhaust and DN32 bottom tar exhaust |

| Protection | Overcurrent, overvoltage, phase loss, overtemperature, soft start, etc. |

| Maintenance | Electric hydraulic push rod furnace cover, easy for inspection and maintenance |